Please accept all cookies to view the external content.

100 年的经验积累出有史以来最好的慢走丝线切割机床

-

极高的准确度

优化的机械结构、新的 3D 打印机头设计和基于 AI 的温度管理,是实现前所未有的准确度和表面质量的基础。

-

简单

无论对专家还是初学者来说都是一样的简单和灵活。得益于碰撞保护、穿线前的电极丝退火、新的 HMI 和选件可在短短几分钟内从开放式导丝器变切换封闭式导丝器。

-

快速

凭借直接供电的智能电源 (IPG-DPS) 和独特的双线技术,我们能以无与伦比的速度切割。

Please accept all cookies to view the external content.

Please accept all cookies to view the external content.

易于更换的开放式和封闭式导丝器

更换组件

导丝器设计为可轻松快速更换组件

Please accept all cookies to view the external content.

最大灵活性

您可以为每个不同的应用选择正确的导丝器

极高的准确度

减少了从导丝器到工件的距离,提高了电极丝的稳定性。

巧妙的热补偿装置

基于 AI 的温度管理

算法和传感器可预测和减少热影响,并补偿轴变形

超高间距精度

在环境温度变化高达 +/- 2.5 摄氏度时,定位准确度为 +/- 1 微米

Please accept all cookies to view the external content.

双丝线:自动换线装置(AWC)

Please accept all cookies to view the external content.

AWT:自动穿丝

Please accept all cookies to view the external content.

电极丝退火

AWT 的退火过程中可加热张力轮和下工作头之间的电极丝,然后用空气喷射冷却电极丝,并将其拉伸以减小其直径,使电极丝退火并延伸至特定长度。这会产生无毛刺的热切割和圆锥形的末端,易于穿过导丝器和工件。

优势

- 即使在最困难的条件下,也能确保加工中正确的重穿丝

- 在无人值守操作期间,多孔凹模与极进模板起割点自动穿丝及加工。

- 实现顺畅的自动化应用

Please accept all cookies to view the external content.

UNIQUA HMI

Please accept all cookies to view the external content.

UNIQUA 是适用于线切割机床的全新 GF 加工方案的人/机界面 (HMI)。它代表了超过一个世纪的 EDM 技术的巅峰——以及我们之前 HMI 的最佳功能和可用性(人体工程学)的完美组合。

每个技能水平

UNIQUA 对电火花线切割专家和初学者而言都是理想选择。专家可以使用

其强大的功能,而初学者可以利用其易用性

和简短的学习曲线。

UNIQUA 的每种方法

都能按照您想要的方式工作。通过更新后的基于 ISO 的功能或利用面向对象编程的灵活性。

每位用户

离线或在机器上工作。UNIQUA 可确保与主要 CAD/CAM 程序的兼容性,还能提供具有集成 CAM 的强大图形工具。

X 技术

X 技术是一套针对 CUT X 设计进行完美优化的切割技术,它浓缩了有史以来最好的慢走丝线切割机床的所有价值。

极高的准确度

得益于 CUT X 从导丝器到工件的最小距离,以及冲液水路的革命性设计,X 技术致力于获得超高轮廓准确度结果。

简单

操作员无需在精度、表面质量或速度之间做出妥协。X 技术旨在通过一组独特的技术,在所有 3 个特征中达到最佳效果。就这么简单。

操作员只需在 UNIQUA HMI 中选择电极丝、工件材料、高度、导丝器系统(开放式或封闭式)和单线或双线电路。X 技术可以完成其余任务。

快速

X 技术也是最快的技术,确保了 CUT X 机床的极高生产率和较短回报周期。而且,快速还意味着具有成本效益的可持续性,因为电极丝消耗被降到最低。

规格

CUT X 350

| Machine | |

| Type of machining | Submerged wire cutting |

| Dimensions of complete equipment * | 2520 x 2340 x 2154 mm 99.21 x 92.12 x 84.8 in |

| Total weight of the equipment without dielectric | 3900 kg 8598 lbs |

| Machining Area | |

| Work tank | Automatic drop tank |

| Accessibility | Front + Left sides |

| Max. workpiece dimensions * | 800 x 550 x 250 mm 31.49 x 21.65 x 9.84 in |

| Max. workpiece weight without bath | 450 kg 992 lbs |

| Dimensions of table ** | 680 x 450 mm 26.77 x 17.71 in |

| Floor-to-table distance | 1000-1100 mm 39.37-43.3 in |

| Total volume of dielectric fluid | 700 l 185 gal |

| Dielectric level adjustment | 0 – 250 mm (automatic) 0 – 9.84 in (automatic) |

| Dielectric type | Deionized water |

| X, Y, Z and U, V axes | |

| X, Y, Z travel * | 350 x 250 x 256 mm 13.78 x 9.84 x 10.08 in |

| U, V travel ** | ± 70 mm 2.75 in |

| Max. speed (X, Y and U, V axes) | 3 m/min 9.84 ft/min |

| Max. manual position speed | 2 m/min 6.56 ft/min |

| Linear glass scales | Standard on 4 axes (X,Y,U,V) |

| Integrated Collision Protection (ICP) | Standard on 5 axes (X,Y,Z,U,V) |

| Taper machining | |

| Max. taper | 30°/100 mm 3.94 in |

| Electrical supply (machine) | |

| Three-phase input voltage | 400 V ±10% |

| Maximum consumption | 10.4 kVA |

| Compressed air connection | |

| Pressure | 0.6 – 0.8 Mpa 87-116 PSI |

| Maximum consumption | 150 l/min 40 gal/min |

* Width x depth x height ** Width x depth

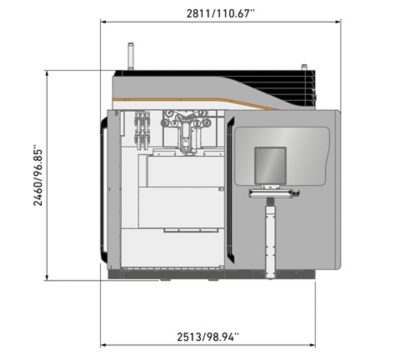

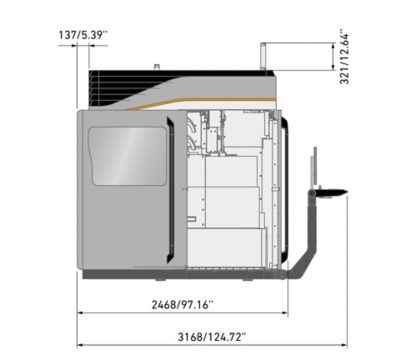

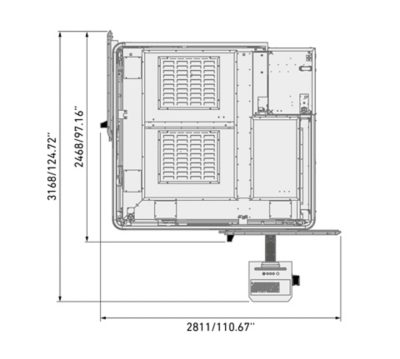

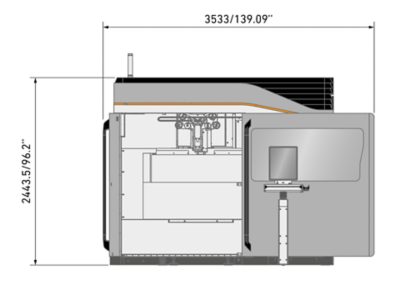

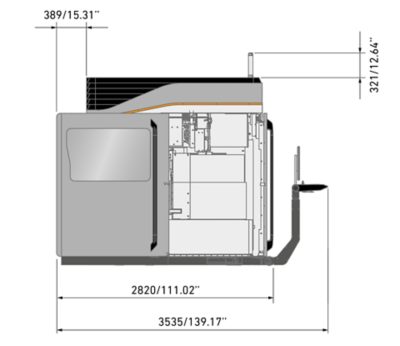

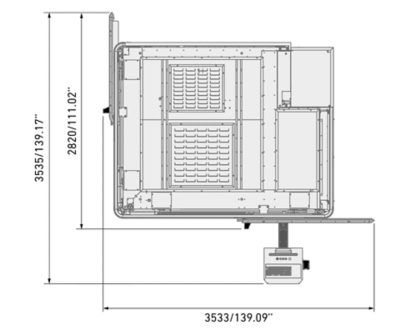

技术图纸

CUT X 500

| Machine | |

| Type of machining | Submerged wire cutting |

| Dimensions of complete equipment * | 2822 x 3533 x 2444 mm 111.1 x 139.09 x 96.22 in |

| Total weight of the equipment without dielectric | 4700 kg 10362 lbs |

| Machining Area | |

| Work tank | Automatic drop tank |

| Accessibility | Front + Left sides |

| Max. workpiece dimensions * | 1050 x 700 x 250 mm 41.34 x 27.56 x 9.84 in |

| Max. workpiece weight without bath | 800 kg 1764 lbs |

| Dimensions of table ** | 850 x 450 mm 33.46 x 17.71 in |

| Floor-to-table distance | 1000-1100 mm 39.37-43.3 in |

| Total volume of dielectric fluid | 950 l 251 gal |

| Dielectric level adjustment | 0 – 250 mm (automatic) 0 – 9.84 in (automatic) |

| Dielectric type | Deionized water |

| X, Y, Z and U, V axes | |

| X, Y, Z travel * | 500 x 350 x 256 mm 19.68 x 13.78 x 10.08 in |

| U, V travel ** | ± 70 mm 2.75 in |

| Max. speed (X, Y and U, V axes) | 3 m/min 9.84 ft/min |

| Max. manual position speed | 2 m/min 6.56 ft/min |

| Linear glass scales | Standard all axes (X,Y,U,V) |

| Integrated Collision Protection (ICP) | Standard on 5 axes (X,Y,Z,U,V) |

| Taper machining | |

| Max. taper | 30°/100 mm 3.94 in |

| Electrical supply (machine) | |

| Three-phase input voltage | 400 V ±10% |

| Maximum consumption | 10.4 kVA |

| Compressed air connection | |

| Pressure | 0.6 – 0.8 Mpa 87-116 PSI |

| Maximum consumption | 150 l/min 40 gal/min |

* Width x depth x height ** Width x depth

技术图纸

视频和手册

CUT X 系列视频

Please accept all cookies to view the youtube video content.

让我随时了解最新情况

Please accept all cookies to view the external content.