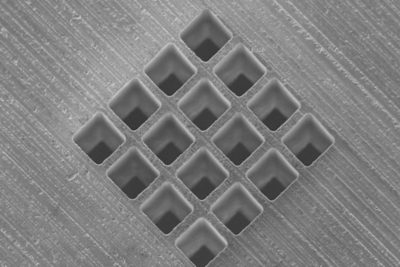

Probe card guide plate

In semiconductor device manufacturing, probe cards are used to correctly identify the quality of etched dies on silicon wafer. A probe card contains a guide plate which facilitates uninterrupted assembly of wafer probing pins. Our Microlution ML-5 Femto Laser solution allows to tackle advancement in 5 nm - 3 nm semiconductor wafer testing:

- Create square-shaped holes to achieve high hole density on guide plate and gain productivity in wafer testing

- Rigid machine design to guarantee pitch accuracy over long machining hours

- Femtosecond laser source to achieve low corner radius, thin walls and taperless bottom cavity

- Increased output with hole drilling rate less than 2 s per hole

Lead frame progressive die tool

IC package lead frames for through-hole, chip carrier, flat or small outline IC packages are manufactured through progressive stamping technology to meet market demands in designs and volume. Our Wire EDM solutions provide:

- High accuracy punch and die cores, and micron level clearance

- Automatic Twin Wire technology for 30% faster roughing and finish

- Thin Wire technology for sharp edges and high surface finish

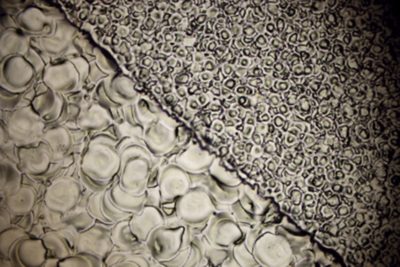

IC encapsulation mold tool

Semiconductor wafer die and leadframe are encapsulated together with EMC (Epoxy Molding Compound) resin in thermoforming or compression molds to create IC chips. Our Die-sinking EDM solution for semiconductor molding achieves:

- Perfect flatness and VDI on cavity surface with 3DS technology to improve the molding process

- Perfect replication and faster production of mold cavities thanks to iGap technology

- Thermally stable machine design for long-term accuracy and precision

Forming, bending, cutting dies for molded lead frame

Our Wire-cutting EDM product line allows mastery over geometrical features in manufacturing of lead frame stamping tools, to guarantee uninterrupted overmolding and assembly.

- Precise machining of tall punch with Automatic Wire Changer (AWC) and thin wire roughing (Ø 0.25 mm) and finishing (Ø 0.1 mm)

- Create desired profiles with sharp features

- Increase productivity on fine geometries by faster machining