Precision parts has a variety of critical surfaces that must meet tolerance requirements to function correctly or to meet aesthetic aspects. In additional cost-efficient recycling helps save on material costs, but it also demands the least-possible contamination of workpiece swarf.

Material challenges

With ceramics, gold for watches and HRC steel for indexable inserts, precision mechanics uses diverse materials that require care to avoid cross contamination that devalues recycling. These materials and the industry's precision parts require reliable tool paths for successful production.

For process cleanliness and continuous process monitoring, Twin Air Sealing (TAS) provides machining analytics and efficiency.

Our market-oriented solutions

Step-Tec HVC 120 platform

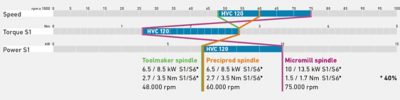

The HVC 120 spindle platform for precision mechanics achieves the highest speeds with good power and torque to create excellent surface quality for small parts from watch bridges to tiny gears, with housing diameters as low as 120 mm. Extreme shaft roundness aids in creating superior surface finishes.

Recommended spindles

The HVC 120 Preciprod spindle is ideal for achieving the highest surface requirements in hard materials using the smallest tools, with a maximum speed of 60,000 rpm and 2.7 Nm (S1) of torque.

Step-Tec HVC 140 platform

The HVC 140 spindle platform achieves high precision and surface quality on small to medium-sized watch parts and all types of gears, with good power and torque in housing diameters as small as 140 mm. Achieve very precise finishes when milling and grinding with a stiff bearing design backed with P2-quality bearings. This platform offers the highest-possible availability through our Spindle Exchange Program (SEP).

Recommended spindles

The HVC 140 spindle is perfectly suited to finishing parts in a single clamping, with a maximum speed of 42,000 rpm and 8.8 Nm (S6 40%) of torque.

Step-Tec HPC 150 platform

The HVC/HPC 150 spindle platform for extended roughing combines the high speed of the HVC platform with greater power and torque, in housing diameters as small as 150 mm. Its advantages apply equally to part production, including watch cases, and to achieving the highest surface quality on plastic molds. We manufacture the extremely round shafts in house to provide excellent surface finishes, while COOL-Core technology and the Opticool System provide reliability through polar temperature stability. For advanced grinding, add an optional AE sensor.

Recommended spindles

The HVC/HPC 150 One Touch spindle is ideal for finishing parts in a single clamping, with a maximum speed of 24,000 rpm and 41 Nm (S6 40%) of power.