Are you still cutting blind?

Your advantages

By cutting these specific work pieces with the ISPS option enabled the process reached a higher efficiency:

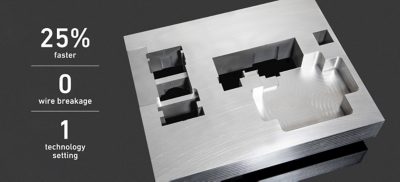

ISPS plate

ISPS plate

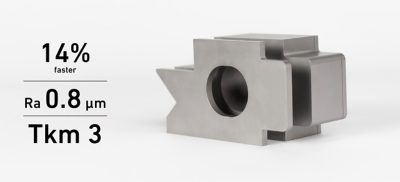

ISPS stepper

ISPS stepper

ISPS stepper 2

ISPS stepper 2

- ISPS plate

- ISPS stepper

- ISPS stepper 2

Watch our video

Aceite todos os cookies para ver o vídeo do YouTube.

Spark Track

Through 50 years of innovation in the area of Wire EDM technology, GF Machining Solutions has become the acknowledged leader in spark generation and control. In 2019 we paved the way for the next generation of Wire EDM machines by mastering each single spark separately, with Spark Track:

- Cutting-edge sensors detect in real-time where each discharge takes place along the wire, as well as its intensity

- This data is then processed using dedicated software

- The information processed results in a multitude of application modules to better control the cutting process

Intelligent Spark Protection System, the first Spark Track module

Thanks to the data collected and processed by Spark Track, the ISPS module is able to use this information to automatically control and adapt the cutting parameters of your Wire EDM machine, ensuring an optimized, safe cutting process:

- No wire breakage

- Machine cuts at maximum efficiency at all times; automatic adaptation to differing conditions

- No need for fine tuning, get a perfect result from the very first cut

ISPS: what our customers have to say

ANB Boumi AG (Switzerland)

Aceite todos os cookies para ver o vídeo do YouTube.

Schulze Werkzeugbau GmbH (Germany)

Aceite todos os cookies para ver o vídeo do YouTube.

ETH Zürich, Institut für Werkzeugmaschinen und Fertigung (Switzerland)

Aceite todos os cookies para ver o vídeo do YouTube.

Make your first step in the Next Generation today!

Get a new machine of the Next Generation: Spark Track ISPS is now available on board of the AgieCharmilles CUT P 350, CUT P 550 and CUT 2000/3000.