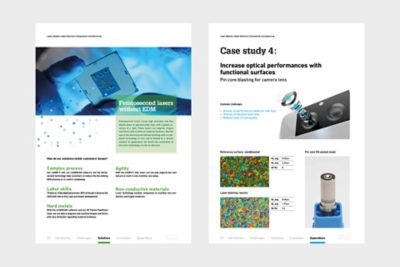

White paper: Laser ablation meets Electronic devices manufacturing

Today, lasers can be combined with or replace traditional subtractive processes in Electronic Components factories. The combination of technologies can improve the results for OEMs' internal mold making or micromachining operations. With greater productivity and profitability than with the traditional methods, lasers can contribute to a dramatically faster workflow. In this white paper, you will learn more about:

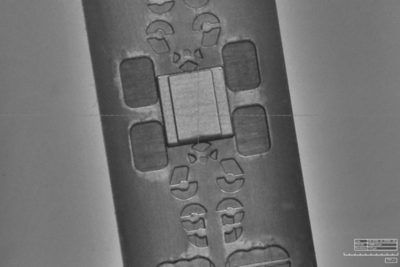

- The current challenges in electronic components micromachining

- How Laser ablation technology tackles these challenges

- Case studies about applications such as microcavities for connectors or pin cores for optical lenses

Expert's talk

In this video, you will discover in detail how Laser solutions work and tackle the new challenges related to the manufacturing processes of Electronic Components like connectors.

- What are the limits of the conventional technologies?

- What can you achieve with the laser technology?

- Case studies

Please accept all cookies to view the external content.

Customer testimonial

Microrelleus (Spain) provides industrial engraving, laser texturing, and laser micromilling. The company offers femtosecond laser services since 2016 and nanosecond laser services since 2013. In this video, Raúl García, CEO, is presenting how Laser has influenced its business and how it supports conventional technologies.

Please accept all cookies to view the youtube video content.

Short product introduction

In this video, Jean-Paul Nicolet, Head of Laser TSE Business Support, is presenting some key components of the LASER P 400 U, our Laser-based solution dedicated to micromachining operations.

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the external content.