The features ISPS, iWire, Turbo Tech and Uniqua are available among all series of the new generation of wire-cutting EDM machines. They offer customers flexibility, an unbeatable speed performance that sets a new benchmark in the industry and maximum machining efficiency, while lowering overall costs and environmental impact by reducing wire consumption.

The CUT P 550 Pro features all four novelties of the new generation of wire-cutting EDM machines.

The CUT P 550 Pro features all four novelties of the new generation of wire-cutting EDM machines.

The Intelligent Spark Protection System (ISPS) can automatically control and adapt the cutting parameters of a wire-cutting EDM machine, ensuring an improved, safe cutting process.

The Intelligent Spark Protection System (ISPS) can automatically control and adapt the cutting parameters of a wire-cutting EDM machine, ensuring an improved, safe cutting process.

The iWire software module reduces wire consumption.

The iWire software module reduces wire consumption.

The graphical intuitive interface Uniqua enables a high flexibility to increase production efficiency.

The graphical intuitive interface Uniqua enables a high flexibility to increase production efficiency.

- The CUT P 550 Pro features all four novelties of the new generation of wire-cutting EDM machines.

- The Intelligent Spark Protection System (ISPS) can automatically control and adapt the cutting parameters of a wire-cutting EDM machine, ensuring an improved, safe cutting process.

- The iWire software module reduces wire consumption.

- The graphical intuitive interface Uniqua enables a high flexibility to increase production efficiency.

Watch our videos

Next Generation of Wire EDM Turbo Tech

Turbo Tech, a new standard technology that is faster than the existing speed technology on wire-cutting EDM machines, is fully compatible with the Spark Track platform. Turbo Tech offers an excellent speed-accuracy compromise in good or bad flushing conditions, is available for all wire types (brass, speed and quality) and fully integrated in Uniqua or AC Cut 2 interfaces. Thanks to the faster final machining time and the resulting lower wire consumption, it is not only a state-of-the art, but also a sustainable technology.

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Next Generation of Wire EDM: Spark Track - ISPS Module

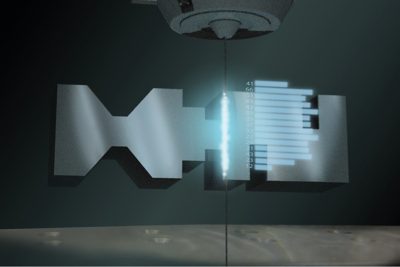

The Spark Track platform, launched by GF Machining Solutions in 2019 has been a breakthrough in wire-cutting EDM, monitoring spark distribution along the wire. ISPS, GF Machining Solutions' Intelligent Spark Protection System, is a module that optimizes the machining process without risking wire breakage. Thanks to the data collected and processed by the Spark Track platform, ISPS can automatically control and adapt the cutting parameters of a wire-cutting EDM machine, ensuring an improved, safe cutting process, avoiding wire breakage, while achieving maximum machining efficiency. The machine adapts automatically to differing conditions without the need for fine-tuning, as the result will be flawless from the first cut.

Next Generation of Wire EDM: Uniqua

Uniqua, the new unique human machine interface for EDM machines, increases the productivity time and allows customers to decide their priorities anytime and get the best out of their machines. Thanks to its intuitive workflow and a short learning curve, it simplifies the operator's life by adapting to his way of working and offering the possibility to change the programs on board as well as a flexible management of the workshop. Integrated help and tutorials are always available, making it easy to use not only for operators accustomed to ISO programming and for seasoned users, but also for novices.

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Next Generation of Wire EDM: Spark Track – iWire Module

iWire is a sustainable, intelligent process that permits an optimization of wire consumption. As an adaptive software module based on the Spark Track platform, it reduces the consumption of wire, especially in cases where pieces present a big variation of height or upper or lower heads cannot be placed close to the work piece surface. The best performance can be reached with certified wires from GF Machining Solutions. Depending on the work conditions and the application, the degree of wire consumption reduction can vary.