Digitalization, smart manufacturing and home automation drive constant innovation in this field, which relies heavily on serial production and requires superior surface finishes. The use of molds increases productivity, and part production largely relies on very small tools.

Material challenges

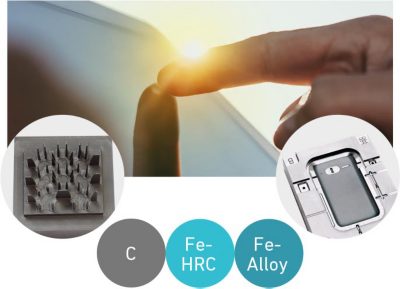

ICT/Electric components use materials that range from mud-sensitive, dust-producing graphite to various steels, including HRC moldmaking steels. Machining graphite requires thermal stability of the spindle and absolute cleanliness of the finished part. Conversely, machining steel demands cost efficiency.

To manage these challenges, COOL-Core technology aids in achieving repeatability and Twin Air Sealing (TAS) tackles even mud-sensitive materials. These spindles offer stiff bearing arrangements for minimal runout that in milling and grinding.

Our market-oriented solutions

Step-Tec HVC 120 platform

The HVC 120 spindle platform for the ICT/EC industry achieves the highest speeds with good power and torque to create excellent surface quality for small LED molds and electrical adapters, with housing diameters as low as 120 mm. Twin Air Sealing (TAS) provides contamination-free production in materials such as graphite. Extreme shaft roundness aids in creating superior surface finishes.

Recommended spindles

The HVC 120 Micromill spindle achieves the highest surface quality and precision, with a maximum speed of 75,000 rpm.

Step-Tec HVC 140 platform

The HVC 140 spindle platform achieves high precision and surface quality on small ICT/EC parts such as smartphone molds or graphite electrodes, with good power and torque in housing diameters as small as 140 mm. Achieve very precise finishes when milling and grinding with a stiff bearing design backed with P2-quality bearings. This platform offers the highest-possible availability through our Spindle Exchange Program (SEP).

Recommended spindles

The HVC 140 Toolmaker spindle is ideal for machining medium-sized high surface quality parts, with a maximum speed of 42,000 rpm and 13 kW (S6 40%) of torque.

Step-Tec HPC 150 platform

The HVC/HPC 150 spindle platform for extended roughing combines the high speed of the HVC platform with greater power and torque, in housing diameters as small as 150 mm. Its advantages apply equally to part production, including gears, and to achieving the highest surface quality on tire molds. We manufacture the extremely round shafts in house to provide excellent surface finishes, while COOL-Core technology and the Opticool System provide reliability through polar temperature stability. For advanced grinding, add an optional AE sensor.