Geometrical control

To prevent wear on machine components

Our expert service engineers tests your machine geometries according to ISO 230-1 specifications.

They provide you with a report detailing the results of our tests, as well as our technical experts’ recommendations for optimizing geometrical precision of your equipment.

Calibration by laser interferometer

To guarantee maximal accuracy of axes

Our expert service engineers checks the precision and the repeatability of the linear positioning of the axes of your machines. The detected deviations will be corrected by modifying the axis correction tables according to VDI 3441 / ISO 230-2.

Circularity test with ballbar gauge

To rapidly diagnose the performance of your machine

The aim of ballbar testing is to compare the effective circle path performed by the machine with the programmed circle path. In theory, if the machine behaves perfectly in terms of positioning performance, both circles should exactly match.

If deviations are detected, recommendations will be provided for precision recovery (e.g., geometrical control, calibration by laser, components exchange).

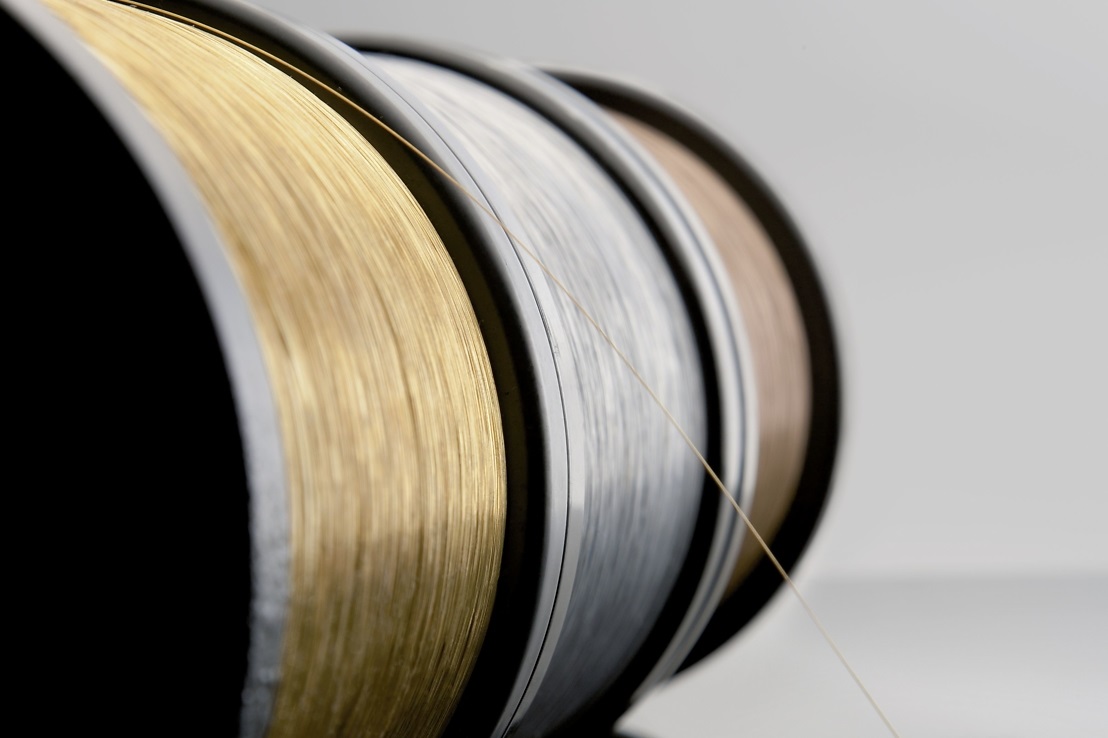

Onsite spindle service

To maximize this critical part's uptime

To keep your spindle accurate and guarantee its high performance, we strongly recommend regular spindle services through a set of dedicated and precise mechanical operations conducted by our expert service engineers using specific tooling.

Spindle service solutions

To ensure your long-term success of your spindle

Through Spindle service solutions, you benefit from the exclusive combined expertise of GF Machining Solutions and original Spindle manufacturer Step-Tec. We make sure that your Spindle runs according your expectations from the first to the last day of usage. We help you monitor your Spindle and take action before an unexpected breakdown. Also, we offer an extended warranty. If issues do arise, you can choose between our 24-hour exchange Spindle service or having us repair your Spindle within 10 days.